The project includes the largest ETFE cushions installed in New Zealand, with individual cushions exceeding 60 m in length, demonstrating the scalability and adaptability of ETFE for major infrastructure applications. The ETFE envelope was custom designed to integrate seamlessly with both timber and steel structures, supporting the architectural vision developed by Studio Pacific Architecture.

Hangar 4

Brand-new Hangar 4 in Auckland, New Zealand, is a landmark aviation project developed for Air New Zealand, combining large-scale timber construction with a high-performance ETFE roof and facade system. The building incorporates the largest single-span timber arch hangar in the Southern Hemisphere, setting a new benchmark for sustainable industrial architecture.

Project Overview

New Zealand

Country

15030

m²

of ETFE

2025

Completed

Studio Pacific Architecture

Architects

At a Glance – ETFE at Hangar 4

- 15,030 m² of ETFE roof and façade cladding

- Largest single-span timber arch hangar in the Southern Hemisphere

- Green Star 6-Star certified by the NZGBC

- ETFE system accommodates structural movement and wind loads

- Reduced structural weight and foundations through lightweight cladding

- Designed, supplied, and installed by Vector Foiltec Asia Pacific

15,030 m²

of ETFE

Large-Span ETFE Roof and Facades for Sustainable Aviation Infrastructure

ETFE was selected to meet demanding performance requirements specific to aircraft maintenance facilities and coastal environments. The structure is subject to significant structural movement, wind exposure, and aggressive environmental conditions. ETFE’s inherent flexibility allows it to accommodate movement without transferring excessive stress to the primary structure, making it particularly suitable for long-span timber and hybrid constructions.

The cushion system uses white top foils combined with dark lower layers, achieving light transmission below 5 % in key roof areas. On the southern facade, fully transparent ETFE cushions were introduced to enhance daylight availability. This controlled approach to transparency balances glare reduction, thermal performance, and visual comfort within the hangar.

Structural Contribution and Environmental Performance

The cushion system uses white top foils combined with dark lower layers, achieving light transmission below 5 % in key roof areas.

Beyond enclosure, the ETFE roof plays an active role in the building’s structural behavior. The cushion arrangement helps distribute wind loads across the primary structure, reducing peak loading on the timber arches. The lightweight nature of ETFE significantly reduced the size of supporting elements and foundations, contributing to material efficiency and lower embodied carbon.

Natural daylight and heat retention provided by the ETFE envelope minimize reliance on artificial lighting and mechanical heating or cooling. These passive benefits are supported by destratification fans, which help maintain stable internal conditions suitable for aircraft maintenance operations.

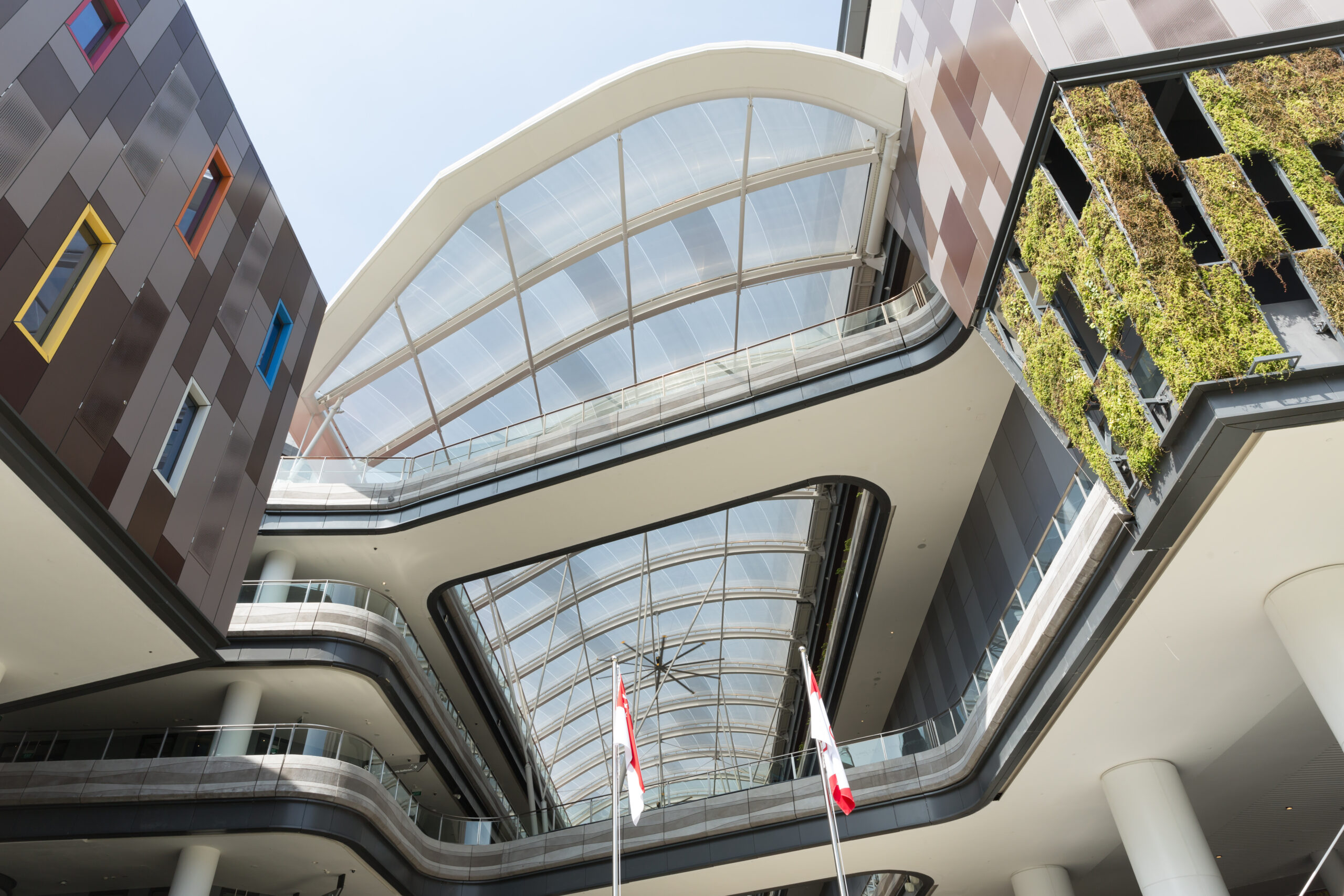

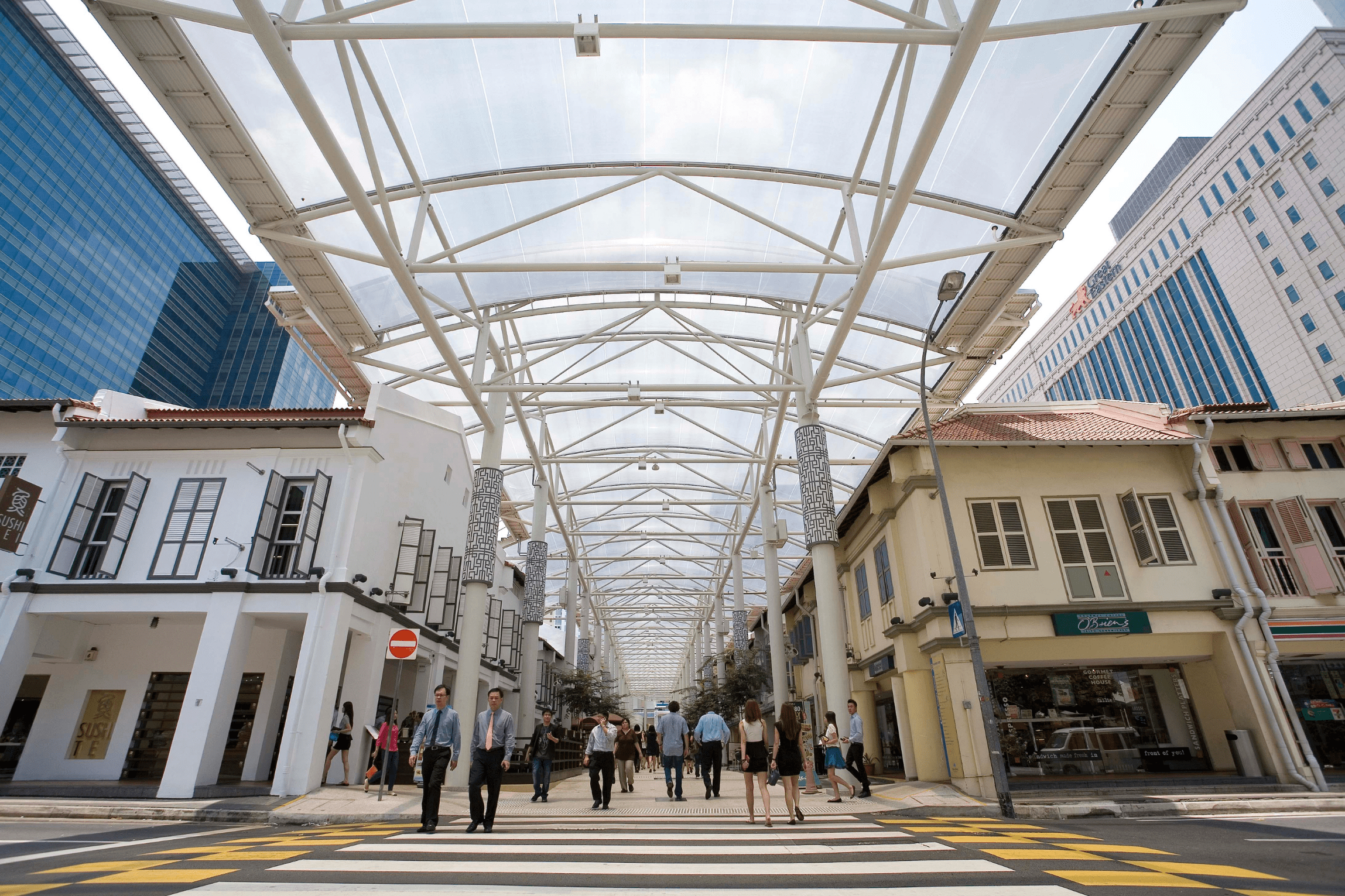

Visual Journey

Click on the pictures to see the full size

Sustainability and Certification

Hangar 4 is the first project in the Asia-Pacific region to achieve a Green Star 6-Star rating under the New Zealand Green Building Council (NZGBC) certification system – a globally recognized benchmark for sustainable building design, construction, and operation.

The combination of mass timber construction and an ETFE roof system supports a reduced carbon footprint through lower material use, recyclability, and long service life. ETFE’s durability in coastal and aggressive environments further enhances the building’s long-term performance.

Scope and Delivery

Vector Foiltec Asia Pacific was responsible for the design, fabrication, supply, and installation of the ETFE cushion system, including two- and three-layer cushions and flashings integrated with timber and steel interfaces. From initial discussions to practical completion, the project was delivered in just under three years.

The project includes the largest ETFE cushions installed in New Zealand, with individual cushions exceeding 60 m in length, demonstrating the scalability and adaptability of ETFE for major infrastructure applications.

Media Copyrights

© Air New Zealand

Read more